Semiconductor / Thin Film

In the semiconductor/thin film industry, sophisticated fitting algorithms is required to enable calculation of the layer thickness down to the nanometer scale such as in the production of silicon wafer. Thousands of our systems are used to control dry etching processes (plasma end-point detection) or inspect layer thickness (ellipsometry).

Featured Applications

Material Characterization of Carbon Nanomaterial

Nanomaterial crystallinity characterization for Silicon or Graphene is an important part of the semiconductor manufacturing.

With high speed Raman spectrometer, we can offer both online and lab measurement to monitor the characteristic of different carbon nanomaterials.

Solar Panel Production

Photovoltaic and solar-heat modules convert sunlight into useable energy; thus this conversion efficiency is an important parameter. The efficiency is optimized by applying thin-film coatings which enhance absorption on various materials. The coating layer thickness influences the efficiency of the solar cells so that optical thickness and uniformity of a coating has to be carefully monitored during production.

We offer an online optical measurement system that can be integrated into the production line to monitor not only the thickness and uniformity but also the surface colour and appearance too.

Etching Bath Measurement

Acidic etching is a widely used texturing process in solar cell fabrication. Application liquids like HF, HNO3, H2SiF, HCl, H2O2, KOH and NaOH are usually used. In order to obtain a reproducible results, the concentration of the main components is essential.

Our UV/NIR spectrometer can acquire a characteristic spectrum of the etching bath for different mixture. It allows a fast in-line analysis as compared to the widely-used traditional method of Ion Chromatography and titration.

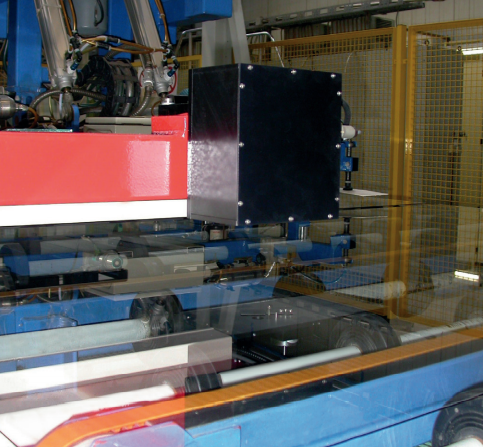

Online Measurement of Dip-Coated Panes on Roller Belts

The layer thickness, the reflection and transmission properties of the dip-coated flat glass have to be measured at exactly the same spot of the glass pane during the production and the final inspection in order to comply to the highest standards for refined flat glasses.

Coupled with our OptiSpec software, our UV-Vis-NIR inline spectrometer system can provide a non-destructive measurements with 100% final inspection of the “invisible” glass products directly on the roller belt.

Our optical setup allows the simultaneous acquisition of transmission and reflection spectra at the same position. Layer thickness is derived from the acquired reflection and transmission values